Machines & Components

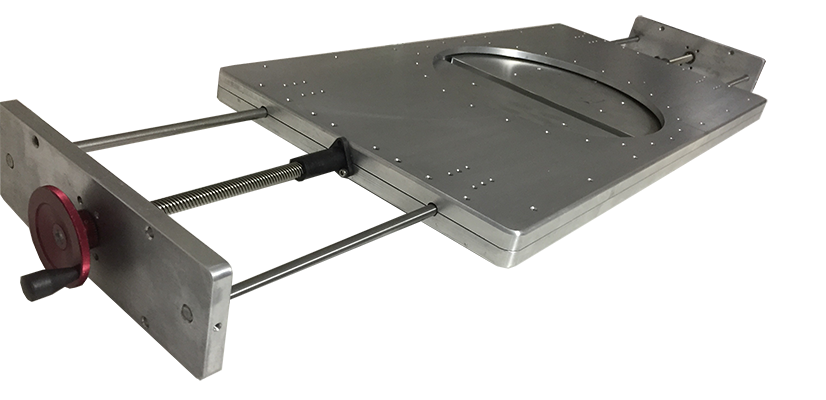

Shear RAM

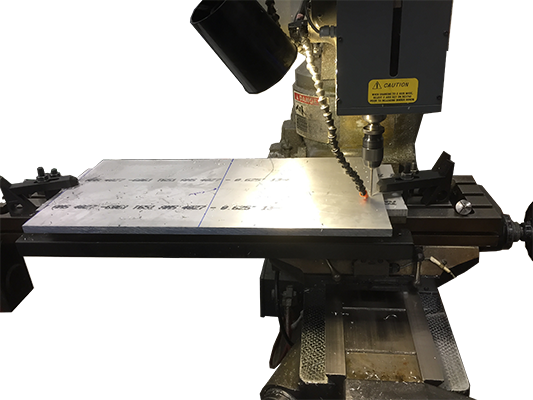

I needed to have an adjustable blade system to serve as a shear ram geometry generation in a testing chamber. After meeting with my mentors I went ahead designed the parts, and manufactured the whole thing within a two day period. If you know the limits of the machines and can appropriately setup the operations using CNC machines, it is amazing how much you can finish in very little time.

HAWK PhD Prototype

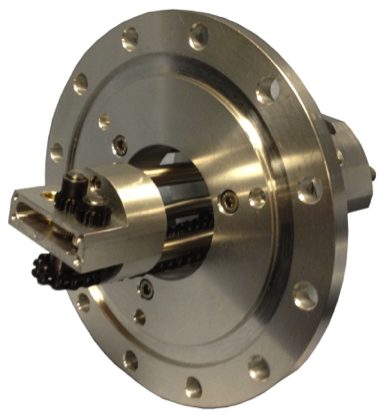

The Hampering Active Wellbore Kit (HAWK) Tool was developed after the Deepwater Horizon accident as a means to rapidly & controllably bring a free flowing oil well under control thus mitigating the damage to the environment and spill cost. The photo below shows the prototype designed for a 4 inch flow chamber. The test was done thanks to the Somerville fire department that brought a firetruck to simulate an "uncontrolled" flow rate from an oil well.

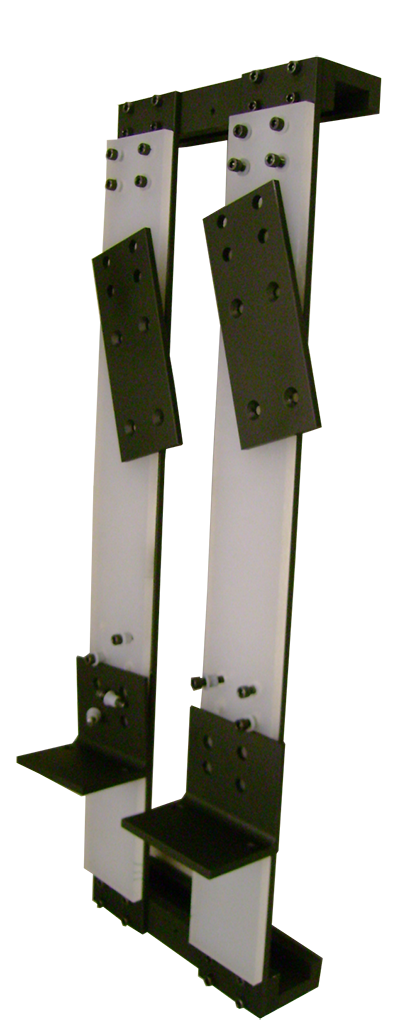

Golden Feeder

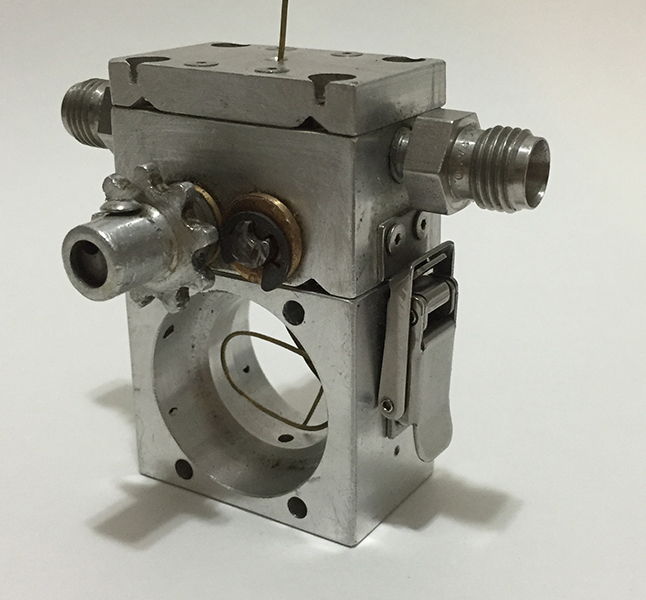

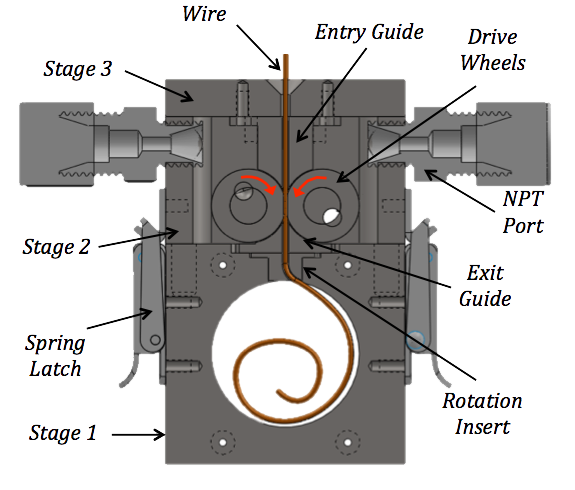

This is the wire feeder that I used to test different feed angles for generating tangled wire mass. When I was designing the unit I noticed that the aspect ratio where close enough that I could make it to the golden ratio. I played with the design and succeed! Feeder is to the Golden ratio of 1:1.618:2.618 and also when you take off stage 2&3 the stage 1 is 1:1 and stage 2&3 combined is to the ratio of 1:1.618! Have to love geeks!

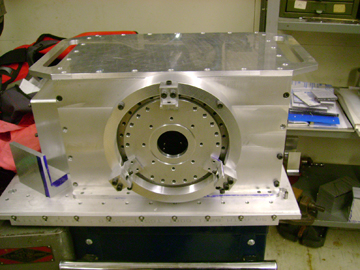

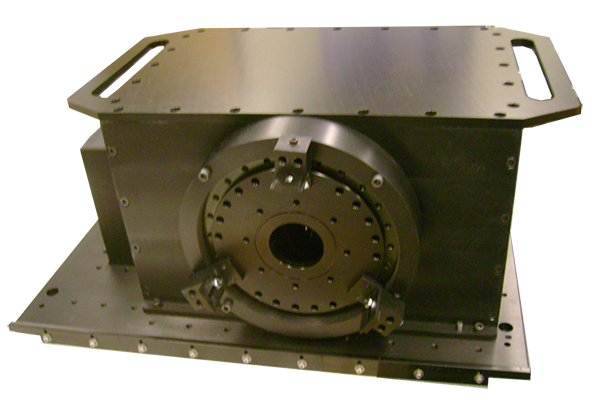

MagIC II Upgrade

I was assigned as the Chief engineer for the MagIC II upgrade for one of the Magellan Telescopes in Las Campanas Chile. I had less than six month's to complete the work of installing a E2V ccd along side the existing 2x2 MagIC chip. The best part shipping all the equipment Chile, and leaving the facility screw amazed that I was able to put it all together in one day. The rapid mounting of the equipment is attributed to a bracket that clamps on to the existing threaded holes. There was no need to machine at the facility!. So I had a week to hike around the area and help out with observations.

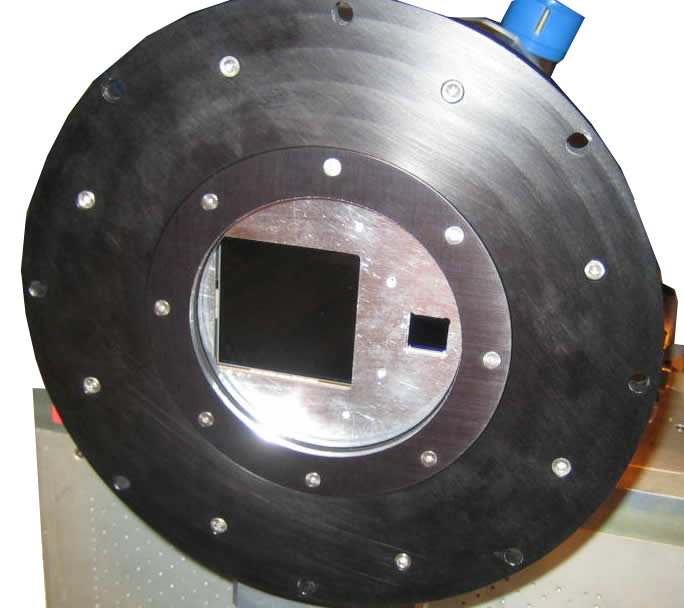

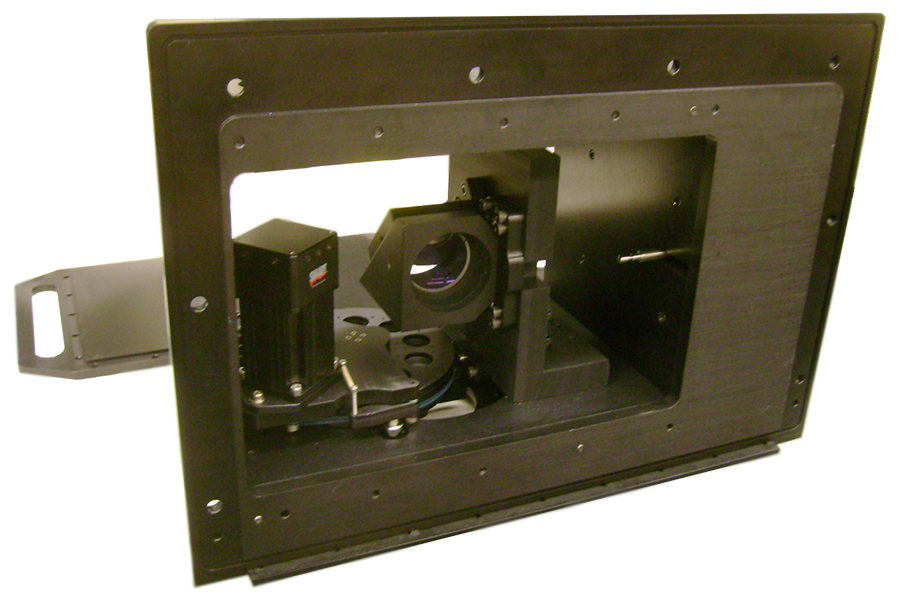

POETS on IRTF

Prof. Jim Elliot was AMAZING! He would give me responsibilities that would challenge me as a project manager and an engineer. He asked me to take on the design review and manufacturing of the interface that allows the POETS fast CCD camera to be mounted on Mauna Kea observatory in Hawaii. The filter wheel and the shutter where purchased components, everything else I manufactured at Edgerton Student Shop.

DARE2MAKE CHALLENGE

Find Your Passion

Invest in Education & Growth

Make Something Amazing

Follow the White Rabbit

- Electronics

- Leather

- Machines & Components

- Mill

- Product Teardown

- Welding

- Woodworking

- Comming Soon

- -Case Studies

- -Design Process

- -Lathe

- -Programming

- -Professional Eng.

- -Waterjet

- -Welding