PE Overview: Mechanical Engineering - Machine Design

Intro

The goal of this page is to help engineers in training who would like to take the PE exam and need clarification on some topics. Note that I can not disclose the questions in the PE exam. My only guide is the handout provided by NCEES for the material content. The sample questions that I create are based on product tear-downs, patents, etc.

The PE Exam is an awesome summary of all of the material that you should know as a mechanical engineer. Think of the exam like an eight hour marathon. Like a marathon, you need to train in order to accomplish the objective. Knowing the information does NOT guarantee you that you will pass the test. You literally have to train for the test. The PE is a timed exam! I took the PE in Oct 2017 and got a 91% on the first try (normally the exam score is not revealed when you pass, Texas however gives you the score). The best part is that I internally know which were the questions I got wrong and why after taking the exam.

There are three distinct PE Mechanical Engineering Exams. You have to choose the exam specification that you would like to take: 1) HVAC and Refrigeration, 2) Machine Design and Materials, and 3) Thermal and Fluid Systems. You should choose your strongest subject. I selected Machine Design and Materials and the sample problems here are for the Machine Design exam. The challenge is that most of the References for the PE Mechanical are outdated. The NCEES exam specifications for machine design changed starting the April 2017 exam. So we are left with outdated references and limited number of practice problems. It was a great deal of work just getting enough relevant problems for each topic. Hence why I was inspired to create this website.

Table of Contents

Where to Start

General Requirements

Before you Begin

What to Buy

Study Strategy

Where to Start

You should ideally start the process during college while you have the full breath of mechanical engineering knowledge fresh in your mind. In reality you should start when you are in college because life may get in the way afterwards. You should take the Fundamentals of Engineering (FE) exam your senior year in college (it will also help for job interviews). 1) Take FE exam. Go through the National Council of Examiners for Engineering and Surveying (NCEES). 2) Track your engineering experience throughout your career. Key words: Design & Analysis 3) Take PE exam. Depending on the state that you are applying for licensure, the PE exam can be decoupled from the experience. 4) Complete your Supplementary Experience Record (SER) 5) Complete recommendations (via SER) and applications

Familiarize w/ Requirements

The requirements to take the PE exam vary by state. There are two major categories: 1) states that couple the experience to the PE exam, and 2) states that de-couple the experience to the PE exam. Basic Process (coupled) 1) ABET Accredited Engineering Degree 2) FE EXAM 3) Complete Professional Experience 4) Submit Full License Application 5) PE Exam 6) Get your engineering license * States that are coupled (Verified Dec 2017): Arkansas, Maine, Massachusetts, New Hampshire, ... Basic Process (de-coupled) 1) ABET Accredited Engineering Degree 2) FE EXAM 3) Eng. in Training Cert. (vary by state) 4) Take PE Exam 5) Complete Professional Experience 6) Submit Full License Application 7) Get your engineering license * States that are de-coupled (Verified Dec 2017): California, Illinois (May 2018, application), Louisiana (EIT & App), New Mexico (2 yrs, App), Oklahoma, Texas (EIT)...

General Requirements

The licensure process focuses on three elements: education, examination, and experience.

These are the basic requirements: A) Engineering Degree (4 yrs) from accredited University B) Pass the Fundamentals of Engineering (FE) exam C) Pass the Principles and Practice of Engineering (PE) exam D) Complete 4+ years of progressive engineering experience

Before you Begin

Preparing for the PE

As you start this wonderful journey down a rabbit hole to become a professional engineer, you should come to terms with some facts: 1) If you fail to plan, you are planning to fail {Benjamin Franklin} 2) You MUST study to pass (by my estimates at least 200 hours) 3) You NEED to Invest: time, & money (buy ref books, calculator, stickies etc) to pass

What to Buy

Reference books

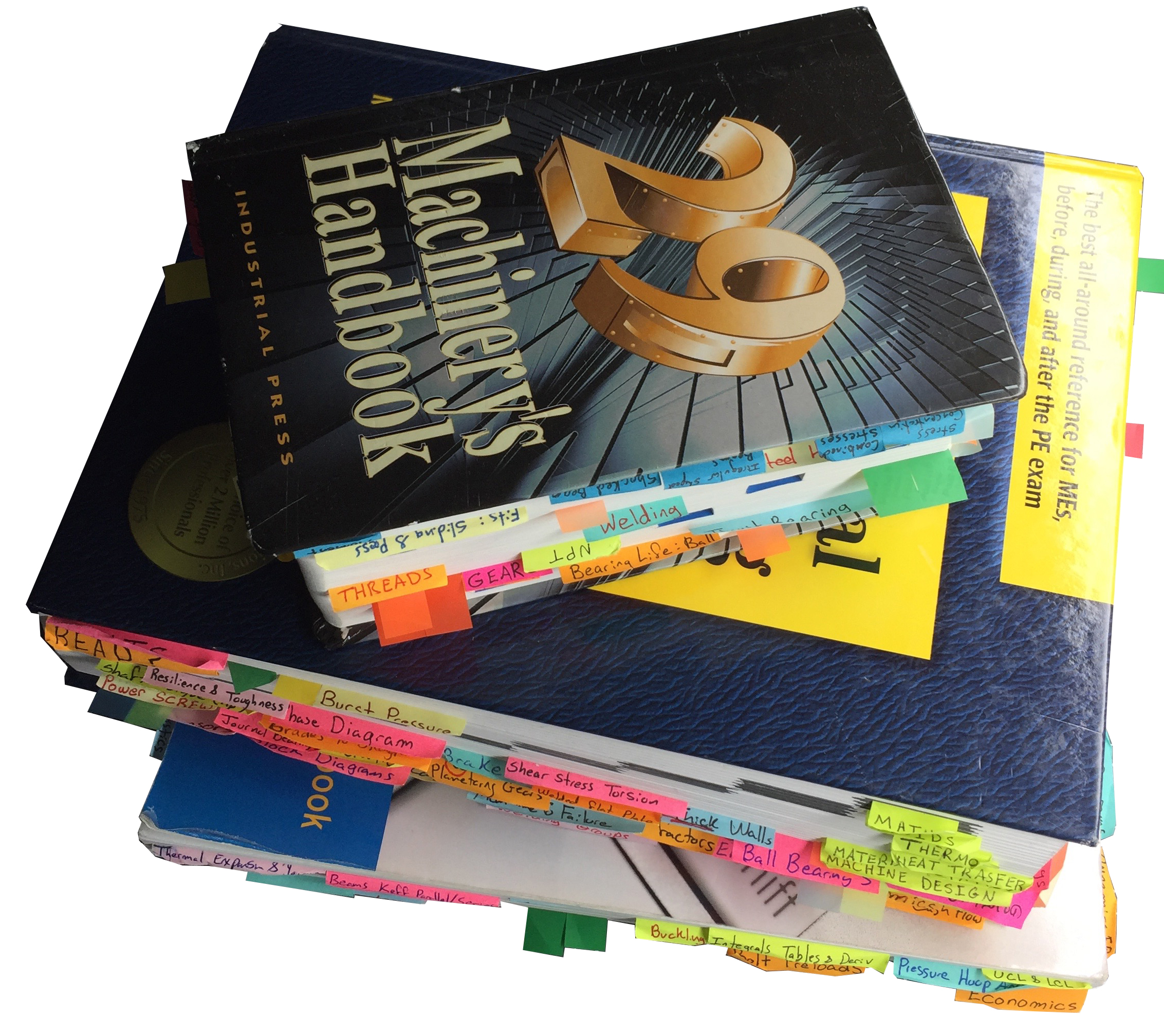

I walked into the test with 20 references. I predominantly used 5 references. Throughout the test I kept referring these five books. If you go into the test without these five references you are losing out. 1) FE Reference Handbook (Either buy latest version or print & 3 ring binder 2) PPI: Mechanical Engineering Ref. Manual for PE Exam (12th Ed was just fine) 3) Machinery's Handbook (29th Ed was just fine) 4) Manufacturing Engineering & Technology (5th Ed was just fine) 5) AIAA Aerospace Design Engineers Guide (5th Ed was just fine)

Your five main references should be marked with stickies. Since the PE exam is a timed exam, rapidly finding the equations/material is an asset. Any reference that you did not do practice questions or have a great familiarity with the content will only hurt you. You may inadvertently waste time searching, when it could have easily been found. If you spend 30 seconds extra to find an equation for half the test (40 questions) that is 20 minutes of time that you could spend answering the more difficult questions. DO NOT WRITE YOUR STICKY NOTES IN PENCIL. MAKE SURE ALL YOUR NOTES ARE IN PEN IN ALL OF THE MATERIAL THAT BRING TO THE TEST. HANDWRITTEN NOTES IN PENCIL CAN COST YOU THE EXAM.

Other Supplies

1) Digital watch with start stop timer (beeps sounds off) 2) TWO calculators (I used TI-36X PRO, verify with NCEES) 3) Sticky notes 4) Protractor & a ruler

Recommend to purchase a TI-36X Pro calculator (This is what will be used in the course). Alternative calculators include Casio (FX-115 family, FX-991 family), HP (HP 33s, HP 35s), and TI (TI-30X family, and TI-36X family).

Study Strategy

Before you begin to study you should make a study schedule. You can do it in what ever form/method that you prefer. The most important part is that you are consistently working through sample problems and start warming up for test taking. I just printed the NCEES exam specification and wrote out a projected weekly progress, which includes a buffer period. My study schedule was made for 15 weeks (HERE). The best way to study is by practice problems, forget about reading 10 hours of text. YOU NEED do sample problems under timed conditions.

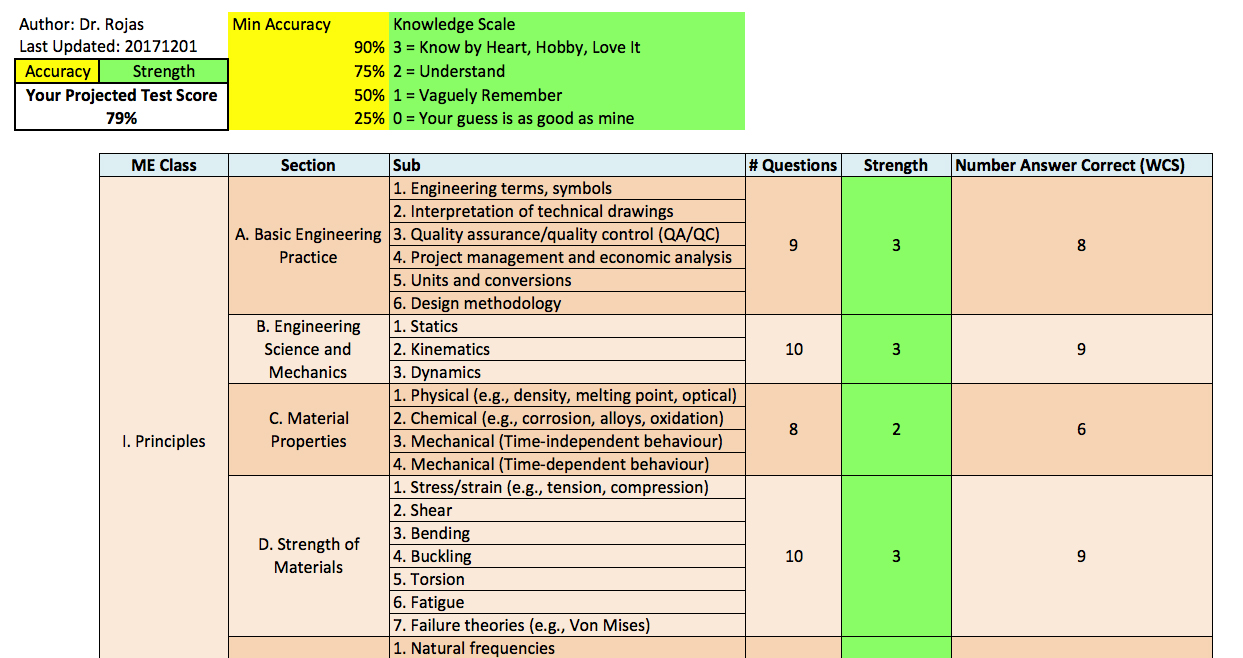

Analyze Performance

As you start doing sample problems you can keep track of the amount of time it takes you complete a problem as well as the average success rate. You will without a doubt start out slow (meaning 5 to 10 minutes) per problem. Eventually as you use the sticky notes and get comfortable with your calculator you can eventually drop that time below 4 minutes for most problems. I created an excel sheet where I predicted my exam performance based on my measurements. By my conservative estimate I should have gotten at least 80% on the test. I actually got a 91%. The accuracy of the excel spreadsheet depends on your dedication to collect the data. The minimum passing score is unknown. I was aiming for a minimum score of 80%, I recommend you should as well.

DARE2MAKE CHALLENGE

Find Your Passion

Invest in Education & Growth

Make Something Amazing

Schedule

- Overview Meche PE

- Product Dev. Process

- Explore → Hands On

- I - Principles

- → Foundation

- → A - Basic Engineering Practices

- → B - Engineering Science and Mechanics

- → C - Material Properties

- → D - Strength of Materials

- → E - Vibration

- II - Applications

- → A - Mechanical Components

- → B - Joints and Fasteners

- → C - Supportive Knowledge

- III - Holistic Knowledge

- → A - Heat Transfer

- → B - Fluid Dynamics

- → C - Controls

- → D - Thermodynamics

- → E - Electronics

- IIII - Precision Machine

- → A - Error Apportionment

- → B - Metrology